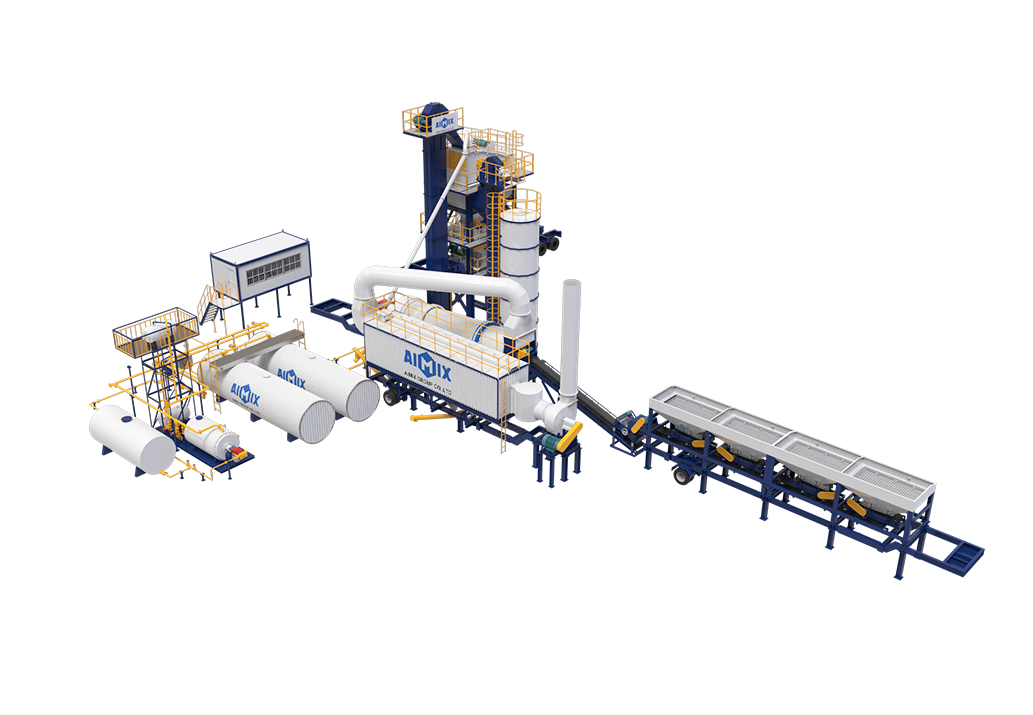

Choosing a suitable asphalt mixing plant is crucial for any construction project involving road paving or maintenance. The right plant can significantly impact the quality, efficiency, and cost-effectiveness of the asphalt production process. This essay aims to provide guidance on selecting an appropriate asphalt mixing plant, considering various factors such as capacity requirements, mobility, and environmental considerations.

Capacity Requirements

Determining the required production capacity is essential in selecting an asphalt mixing plant. Consider the volume of asphalt needed for your project, both in terms of daily output and peak demand. Opt for a plant that matches these requirements to ensure uninterrupted operations and timely completion of projects. For example, if you need to build roads on a large scale and need to work on a large area with a very high demand for asphalt, then you may want to consider a mixing plant with a higher production capacity. If you want to build a rural road or make emergency repairs to the road, the demand for asphalt is relatively small, you can consider the asphalt mixing plant mini (aspal mixing plant mini).

Environmental Considerations

Environmental regulations play a significant role in modern construction practices. Ensure that the chosen asphalt mixing plant(amp aspal) complies with local emissions standards and noise regulations. Look for plants equipped with advanced technologies, such as dust collectors and anti-pollution systems, to minimize air and noise pollution.

Quality and Efficiency

The quality of the asphalt produced directly affects the durability and performance of the paved surface. Assess the mixing plant’s capabilities and features that contribute to high-quality asphalt production, such as temperature control systems, precise weighing mechanisms, and well-designed mixing units. Additionally, efficiency is essential to maximize productivity and minimize downtime. Look for plants with quick setup times, easy maintenance procedures, and reliable performance records.

Mobility

Consider the mobility requirements of your project. Mobile asphalt mixing plants are suitable for shorter-term or smaller-scale projects where frequent relocation is necessary. These plants are easy to transport and set up at different job sites, providing flexibility and reducing the need for additional equipment.

Cost-effectiveness

Consider the initial investment cost, operational expenses, and maintenance requirements when evaluating different asphalt mixing plant options. The price of asphalt plants varies greatly from model to model and output to output. While it can be tempting to opt for the cheapest option upfront, consider the long-term costs associated with energy consumption, spare parts availability, and potential production delays due to equipment breakdowns. Balance the initial cost with the expected lifespan, reliability, and overall value offered by the plant. Learn more about the price of asphalt mixing plant manufactured by Aimix: https://aimixindonesia.id/harga-asphalt-mixing-plant/

Manufacturer Reputation and Support

Choose an asphalt mixing plant from a reputable manufacturer known for producing reliable and durable equipment. Research the manufacturer’s track record, customer reviews, and after-sales support services. A road machine manufacturer will provide technical assistance, spare parts availability, and offer warranties on their products, ensuring smooth operations and minimizing downtime.

Conclusion

Selecting a suitable asphalt mixing plant requires careful consideration of various factors including capacity requirements, mobility needs, environmental considerations, and specific features of mini asphalt mixing plants. By understanding these factors and conducting thorough research, you can make an informed decision that aligns with your project goals, enhances productivity, ensures quality output, and optimizes cost-effectiveness in asphalt production.